Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

Table of ContentsLittle Known Facts About Motorcycle Parts New Zealand Specialists.The 4-Minute Rule for Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists StatementsThe Buzz on Motorcycle Parts New Zealand Specialists4 Easy Facts About Motorcycle Parts New Zealand Specialists ExplainedThe 9-Second Trick For Motorcycle Parts New Zealand SpecialistsNot known Details About Motorcycle Parts New Zealand Specialists Some Known Details About Motorcycle Parts New Zealand Specialists

Get to out to one of our experts today.CNC machining innovation is promptly coming to be the centerpiece of several manufacturing processes around the world as a direct result of its several benefits over various other methods. Furthermore, the sectors that produce bikes have gotten on board with this fad. The most ingenious firms are now establishing their engine components and wheels using machining methods originally developed for motorcycle parts.

On the various other hand, the results of industry are the main focus of this article. Let's obtain right right into it. You may be questioning why we make use of. It is not tough to fathom the elements that caused this outcome. Since we have your attention allow us explain the rationale behind this contemporary growth in the bike manufacturing industry.

Motorcycle Parts New Zealand Specialists - Questions

In addition, you have total control over the appearance of the elements, also down to the minute information. Periodically, motorcyclists may determine to spruce up their trip by mounting aftermarket elements or changing the bike's makeover.

An Unbiased View of Motorcycle Parts New Zealand Specialists

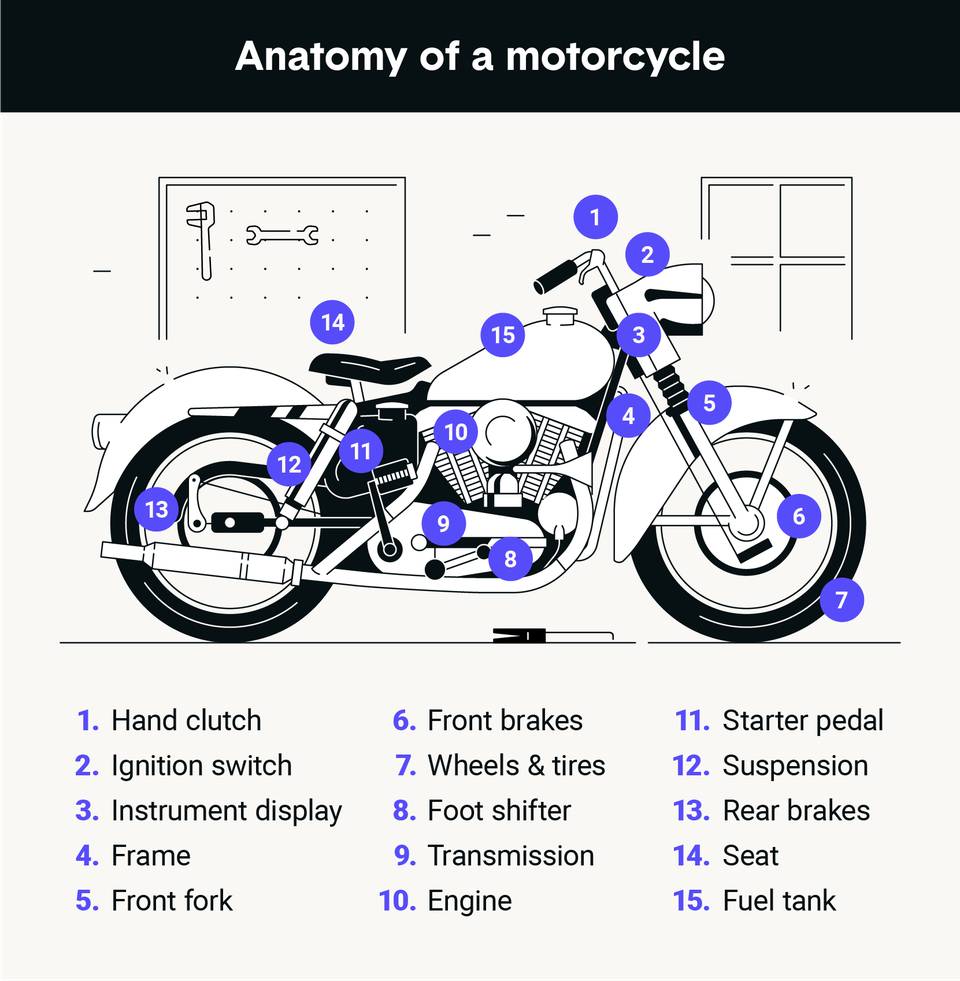

CNC machining might be utilized to make nearly all of a bike's metal and plastic parts. To proceed, we'll go over several machined parts for motorcycles.

When customizing the wheels, the disks are where the emphasis must be. Most of them are made out of aluminum. Aluminum alloys are widely known for the superior machining abilities that they have. Milling procedures are used to acquire the preferred degree of wheel personalization. An additional facet of the bike that might be personalized is the tires.

Facts About Motorcycle Parts New Zealand Specialists Revealed

When it involves a car (or a motorcycle), one of the most crucial component is the engine. A number of individuals allude to it as the "heart" of the car. On the various other hand, the camshaft, the cylinder head, and the pistons tend to be elaborate and require layouts with a high level of accuracy.

Lighting is one more complex aspect of personalization. Use just top quality items, nevertheless, considering that these lights are critical for the safety of motorcyclists and other chauffeurs or individuals on the roadway, specifically in the evening. Motorcycle fronts lights have three almosts all: the bulb, or source of light, the lens, and the housing. Particularly, we tailor the lens and the housing.

Milling procedures with a flawless surface would cause the lenses having a reflective high quality that is similar to that of a mirror. The cover, on the other hand, is not composed of breakable products; rather, it is constructed out of tough polymers that can be machined into more complex patterns.

Facts About Motorcycle Parts New Zealand Specialists Uncovered

They frequently have sophisticated geometries with a riches of minute information. Motorbike manufacturers commonly cast these parts, but just for the production of bespoke components. important site Nevertheless, CNC machining is the approach of selection when generating special pieces. Machining on five axes in today's globe is the ways whereby any kind of layout form may be recognized.

Choose Runsom for your personalized bike parts! Click This Link We have the capability to fabricate complex and fashionable parts making your motorcycle incomparable.

Right here are a few examples of metals often utilized in bike part machining. Light weight aluminum is the main material made use of by firms focusing on creating custom motorbike parts to produce many of these components. In the past, we would certainly develop our engines out of actors iron. On the other hand, light weight aluminum is quickly ending up being the product of selection, partly due to the fact that it is extra lightweight.

Zinc describes another metal that is very light in weight and has wonderful machining high qualities because of its high mechanical stamina. This product might be developed right into practically any kind of form and preserves its measurements well. Even mission-critical components that require a high level of accuracy may take advantage of their usage.

Getting The Motorcycle Parts New Zealand Specialists To Work

An additional steel that sees hefty use in the manufacturing of CNC-customized components is magnesium. It is among the lightest steels that are now obtainable and has superb machinability attributes and stamina compatible with its low weight. Among the disadvantages of magnesium is that its dust might quickly catch fire.

Since of its premium machinability and weldability, stainless-steel is an alloy that is especially fit for CNC processes. Along with this, they have fantastic deterioration resistance and a high visual allure. Their most usual usage in generating different motorcycle elements is bolts, such as screws and screws. Their reduced susceptibility to oxidation and corrosion makes them excellent for this use.

Motorcycle Parts New Zealand Specialists for Beginners

It appears that CNC turning and grating are the fundamental processes. Different techniques exist, such as exploration. Let's explore most of these machining methods comprehensive. The CNC transforming strategy is considered a subtractive production method. In addition, it needs keeping bars of material, usually plastic or metal, ready and afterwards turning a reducing tool to eliminate areas of the product as the product is transformed.

These methods are equally important and produce parts with high precision and regular quality. They are specifically: grinding, laser cutting, and drilling. The term "surface finish" describes post-processes after the initial machining stage. Motorcycle Parts New Zealand Specialists. The processes assist improve the general top quality of the machined bike components. Below are the short intro, advantages and disadvantages of five surface therapy techniques.

The 4-Minute Rule for Motorcycle Parts New Zealand Specialists